Innovations creating customer value

Sandvik Rock Processing Solutions continuously develops services and solutions that help our customers in the mining and infrastructure industries improve their productivity and sustainability.

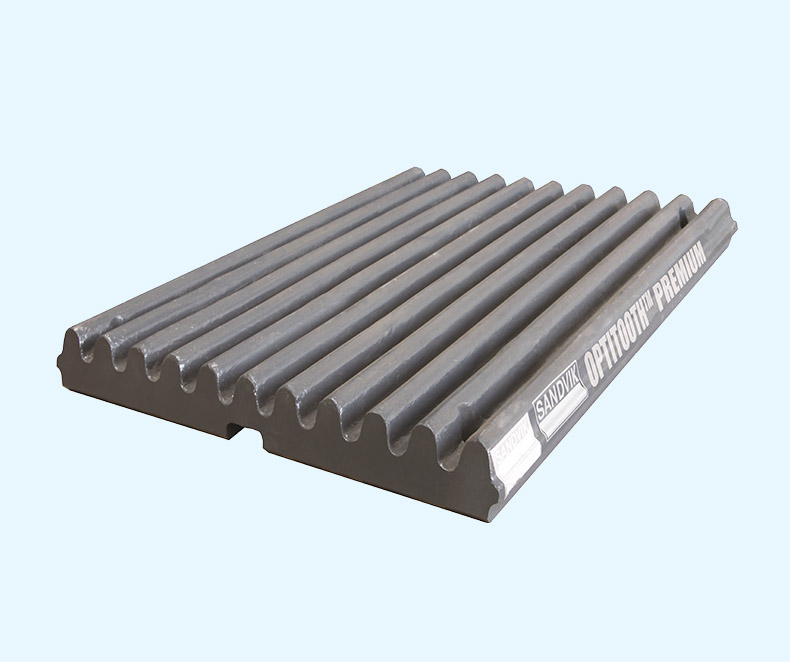

New products and parts, services and consumables offerings are continually being developed. The new Optitooth™ jaw plates, for example, are an aftermarket solution for our mobile crushers that provide a longer lifecycle, higher productivity and reduced fuel consumption.

In 2022 we introduced Sandvik® QA452, a tracked mobile, 3-deck sizing screen. It is a tailored rock processing solution for quarry, recycling and mining industries and the screen was upgraded with uptime, productivity, sustainability and lower cost of ownership in mind. The screen is a hybrid solution, including an electric plug-in option, allowing customers to choose the most economic and efficient energy source. It comes with a Sandvik My Fleet telemetry system and 7-year data subscription as standard. This offers 24/7 fleet management, geo-fencing and remote support.

During the year, we introduced a new wheeled mobile crushing and screening range in North America. All powered by electricity, our wheeled crushers offer a low operational cost per ton and reduce CO2 emissions.

The mobile screen Sandvik® QA452 was upgraded with uptime, productivity, sustainability and a lower cost of ownership in mind.

The new jaw plates last longer, offer higher productivity and have a lower carbon footprint.